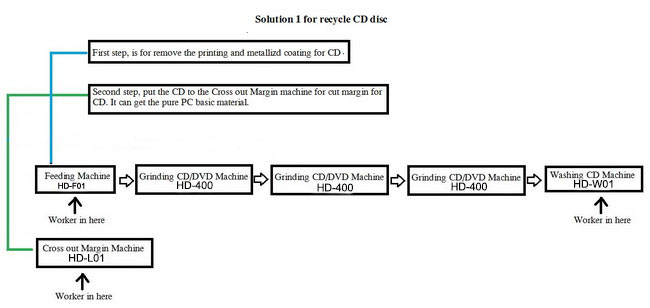

This system include:1. One set Sorting Machine (option). It is for sorting the DVD and the CD, if they are mixture together.

2. One set Feeding CD Machine .This machine is for sending the waste CD to the Grinding CD/DVD Machine. It can made a suitable distance for each CD, for ensure the machine running well.

3. Three unit Grinding CD/DVD Machine. This machine is for separate the metallized coating and printing cover for get the pure PC disk.

4. One set Washing CD Machine. This machine is for clean the metallized coating and printing cover from the waste CD by water and the brush. Then can get the dry and clean CD from this machine.

5. One set Air pressure turning lathe Machine, it easy cross out the margin from the waste CD.

Notice:

1. Working space requirement for one production line: 150~200 sq.m

2. The Air pressure turning lathe Machine need work with an air compressor, our customer can buy from the local market or request we buy and ship from order.

3. This system need work with water and a water pool, water pool requirement is about 10 cubic meter for 1~3 production line.

For recycle CD :

Put the CD to the Feeding CD Machine, then the CD pass the Grinding CD Machine 1, then pass to Grinding CD Machine 2, then pass to Grinding CD Machine 3, last pass to the Wash CD Machine. The CD after pass the Wash CD Machine is very clean without any demetal. After get 20~30pcs clean CD, use the Stainless steel core for string them. Then put them on the Cross out Margin Machine for make the Margin of the CD out ( as you know this Margin are not the pure PC, it attach some glue when the CD production). All CD after pass the Cross out Margin Machine is the basic pure PC material.

To see the Grinding CD Machine working please visit https://youtu.be/lLtJ-MECNyE

To see the Cross out Margin Machine working please visit https://youtu.be/DtNTGJGkMXg

Air pressure turning lathe HD- L01 means Cross out Margin Machine